CNC and manual metal spinning, deep drawing, fabrication, welding, laser cutting, polishing and stamping.

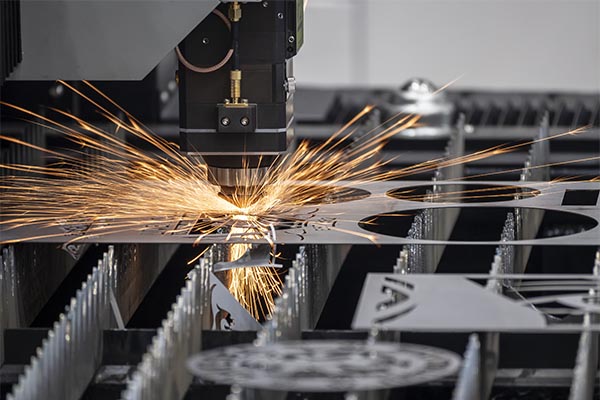

CNC machining, trimming, deburring, piercing, embossing, beading, slotting, laser cutting, plate form rolling, polishing, cleaning, passivating, powder coating, anodizing, etc.

Stainless steel, carbon steel, aluminum, copper, bronze, brass, Inconel, and other formable/exotic metals.

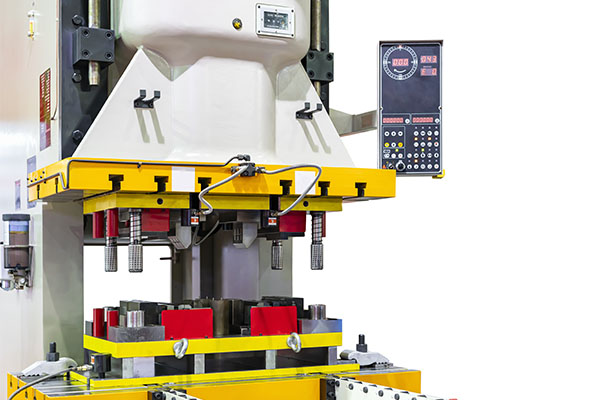

Our press department has both mechanical and hydraulic presses. Our 500 ton hydraulic press can accommodate a maximum part diameter of 60” and a maximum can depth of 16”.

Military, aerospace, medical, cryogenic, municipal, electrical, consumer, industrial, environmental, architectural, appliance, lighting, communications, scientific, hospitality etc.

HMS forms parts that range from the size of a thimble to a satellite dish. We can effectively address both prototype and high volume production requirements. Our manual spinning lathes can swing up to 72" in diameter. Our state-of-the-art CNC spinning lathes can accommodate .200" thick stainless steel, or .315" thick aluminum.

Cans, cones, hemispheres, cylinders, pans, domes, rings, and more.

Our in-house tooling department designs and fabricates all tooling.

Hialeah Metal Spinning Company is dedicated to providing precision metal-formed parts.

We can solve your design challenges. Send your file today for a confidential quote.

© Hialeah Metal Spinning, Inc. All Rights Reserved.