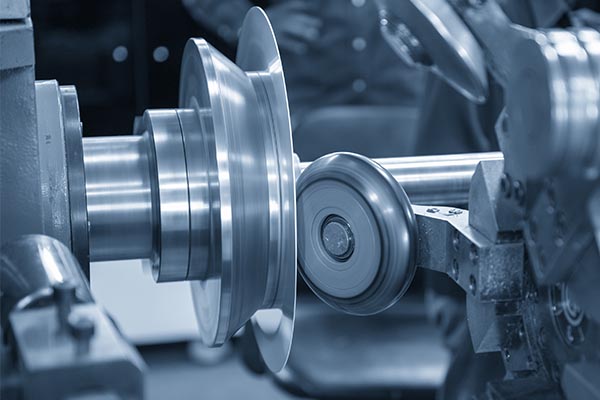

Metal Spinning – Spin Forming – Spun Metal

Spun metal parts from HMS range from the size of a thimble to a large satellite dish. Our manual spinning lathes can swing up to 72″ in diameter, while our automated, state-of-the-art CNC spinning lathes can accommodate a starting disc size of 50”. HMS spins metal parts with wall thicknesses of up to .187″ in stainless steel or .315″ in mild steel.

Each metal spinning application requires different finishes and dimensional tolerances. HMS meets customer specifications by spin-forming custom parts in a wide variety of materials. Although we specialize in stainless steel metal spinning, spun metal parts are produced in these additional materials:

such as titanium, Hastelloy®, and Inconel®.

Regardless of whether your print calls for the manufacture of a new part, or quality and price concerns have you searching for a new manufacturing technique for an existing part, metal spinning can offer significant advantages over other metal fabricating processes such as metal stamping and hydroforming.

Hialeah Metal Spinning Company is dedicated to providing precision metal-formed parts.

We can solve your design challenges. Send your file today for a confidential quote.

© Hialeah Metal Spinning, Inc. All Rights Reserved.